Tailor-made solutions

Your project partner from A to Z

One of Siroco’s strengths lies in the know-how and capacity of our ENGINEERING team to imagine and design optimal, complete and tailor-made heating and air conditioning systems to manage thermal comfort in cab.

With more than 40 years of experience, SIROCO ENGINEERING meets technical and design challenges of world’s leading manufacturers: electrical solutions, dashboard ergonomics, optimisation of the airflow network, etc.

Working with Siroco means entering a dynamic process of project optimisation and support thanks to your dedicated project manager, from concept to series production.

What is your next challenge?

Complete development of thermal solutions

Design & Development

R&D

CFD simulation

Prototypes & Tests

Production & Assembly

Supply Chain

Design & Development

-

Anticipating obstacles

Once your thermal needs are defined, Siroco Engineering draws up specifications detailing all the specificities and constraints of your thermal project. This basis enables our teams to study the feasibility of the project and to offer a detailed technical and commercial solution. This method allows us to anticipate any obstacle.

-

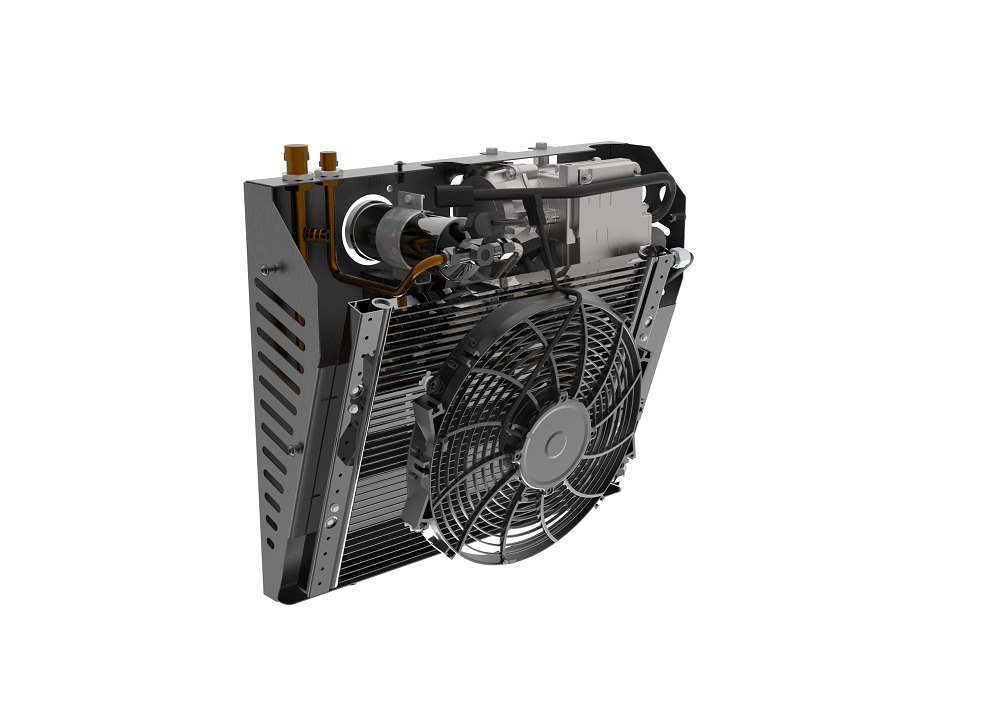

Strong development capacity

We imagine the concept, detail the choice of components – steel, aluminium, thermoforming, injection – and offer a realistic rendering of your HVAC unit integrated into a SolidWorks 3D environment.

R&D

-

Product and process innovation

- actual performance

- technologies

- interfaces

- power consumption

- size

- design

Siroco analyses parameters and systematically optimises your heating and cooling, ventilation and air distribution systems:

Adapting to the specific needs of our customers is the driving force behind our project developments and our performance.

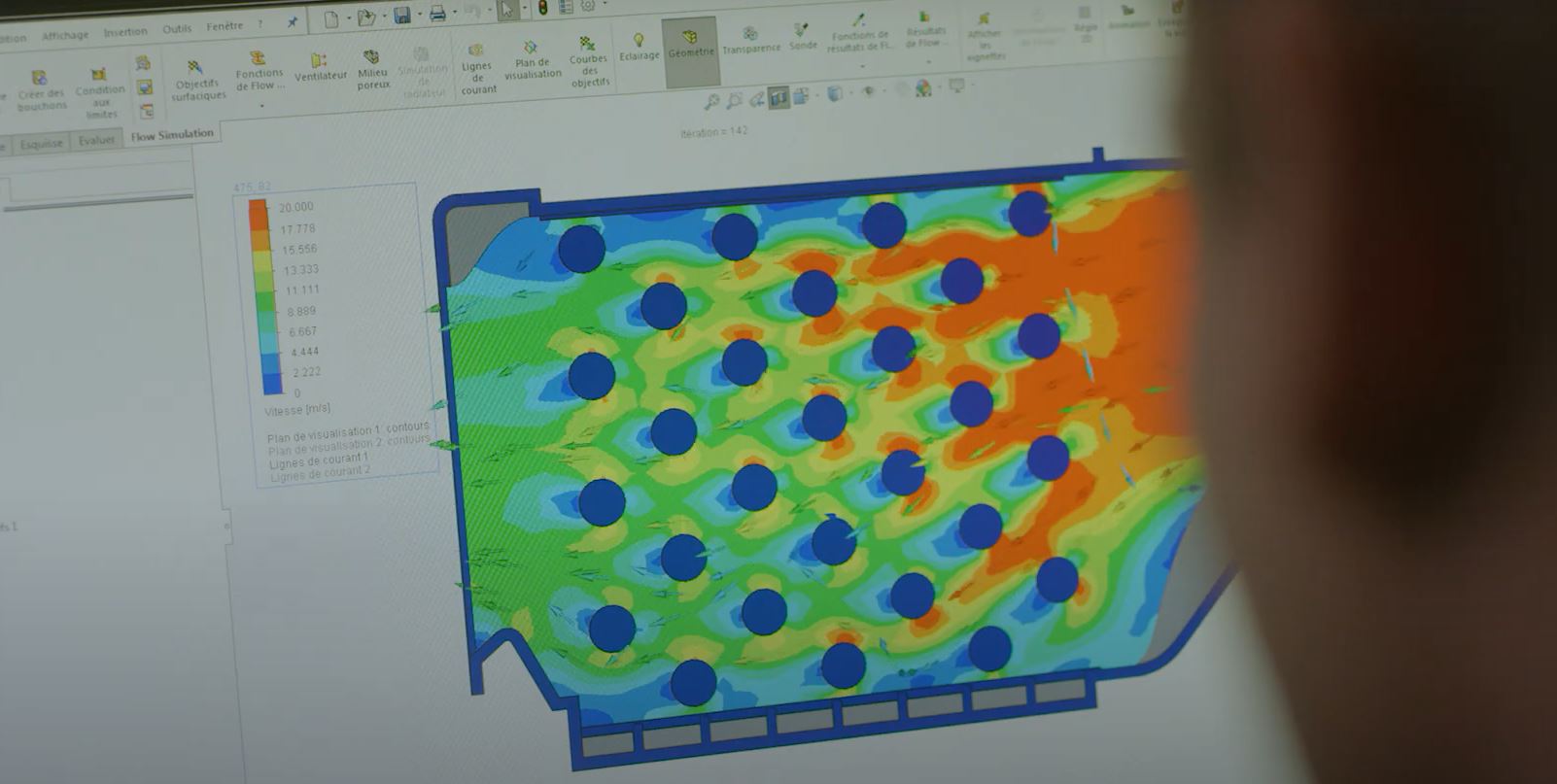

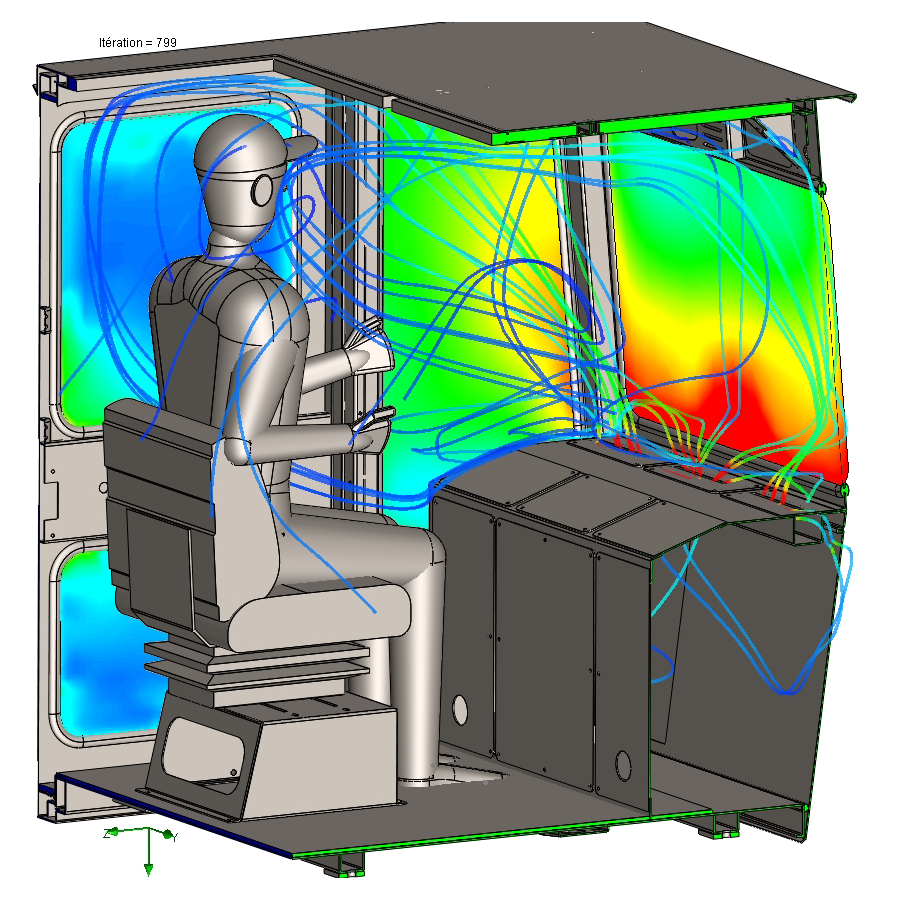

CFD simulation

-

Optimise your HVAC solutions in the development phase

CFD is essential to help you to choose the most optimal solution. CFD simulation is a numerical calculation tool for simulating thermal management and cabin airflow. It is mainly used to optimise your HVAC solutions during the development phase.

-

Reduce development time

Build airflow models, see and correct defects and quantify the performance of your units. Taking defrosting as an example, CFD can be used to evaluate the warm-up time and defrost quality. Thanks to CFD, you reduce the number of prototypes, the overall project cost and the development time.

Prototypes & Tests

-

Prove the ability of the HVAC solution to meet your specific requirements

Extreme climatic conditions, vibrations and shocks, electrical loads, electromagnetic compatibility, life span. Refer to our wide range of technological equipment: airflow measurement bench, thermal performance test bench, endurance bench, reliability tests, electromagnetic compatibility.

-

Climate chamber tests

Our climate chamber welcomes your vehicles up to 6m wide and 2.9m high. We recreate the solar/hygrometric/thermal conditions in which your vehicle will evolve. Do you need to test your HVAC solution without supplying a vehicle? Siroco provides you with its PACKMAT cab on which any type of thermal unit can be mounted. This climatic chamber allows standardised tests to be carried out in accordance with ISO 10263, ISO 14269 and NF EN 1789 methodologies.

Production & Assembly

-

ISO 9001 & ISO 14001 certified

Siroco is committed to providing small to medium-size series and services that meet customer legal and regulatory requirements. Our production methods and processes are continuously monitored and optimised.

-

On-site assembly

Siroco thermal units can be assembled by our qualified assemblers at our site in Genas (France), at our site in Mohammedia (Morocco) or at our site in Pune (India).

Supply Chain

-

Flexibility

Beyond quality, flexibility is at the heart of Siroco’s commitment. Siroco adapts to the supply systems of its customers and fits with their industrial operations.

Values

Project support

Long-lasting relationship

Guaranteed quality

Project support

-

Multi skills

Thanks to our multidisciplinary teams, Siroco brings together on a single site all the skills and know-how you need for the success of your project. With the support of its parent company CLAYENS NP, Siroco gathers skills and best components for each application, such as thermoplastic injection, electronics or harnesses.

-

Customer focus

Your dedicated project manager will support and advise you in every phase of your project: specifications, assessing your thermal needs, calculating components, choosing and optimising the HVAC unit, tooling and design.

We establish a lasting relationship with all our clients through collaborative work and a relationship based on trust.

Long-lasting relationship

-

Collaborative work

Collaboration is essential to the success of your project, Siroco works with its customers to find efficient and cost-effective solutions.

-

From recommendations to knowledge transfer

As market needs and constraints evolve, HVAC units are integrating more and more features: air distribution, filtration, pressurisation, electronic management and multiplexing. We explain all the advantages and disadvantages of the different technical solutions.

Guaranteed quality

-

Meeting deadlines and customer satisfaction

Siroco is committed to meeting your production and delivery deadlines. On a daily basis, all our teams are mobilised to provide you with the best quality / cost / deadline offer. Solidly established on the European market, we are also developing our activity in India, Morocco and Mexico.

-

Zero defect production

Our internal rigour allows us to aim for zero defects and to meet ISO 9001 and ISO 14001 standards.

-

Ensuring the optimal solution

-

Supplies world's leading manufacturers

-

High technical skills

-

Quality assurance